Introduction: Redefining Mobility Engineering

Imagine gliding seamlessly from a cramped airline aisle to a sun-drenched park incline, the boundaries of your world expanding with every smooth turn. For many, the search for the perfect mobility aid feels like a constant compromise. You often have to choose between a tank-like heavy-duty chair that eats up storage space or a flimsy travel scooter that rattles your bones on anything rougher than carpet.

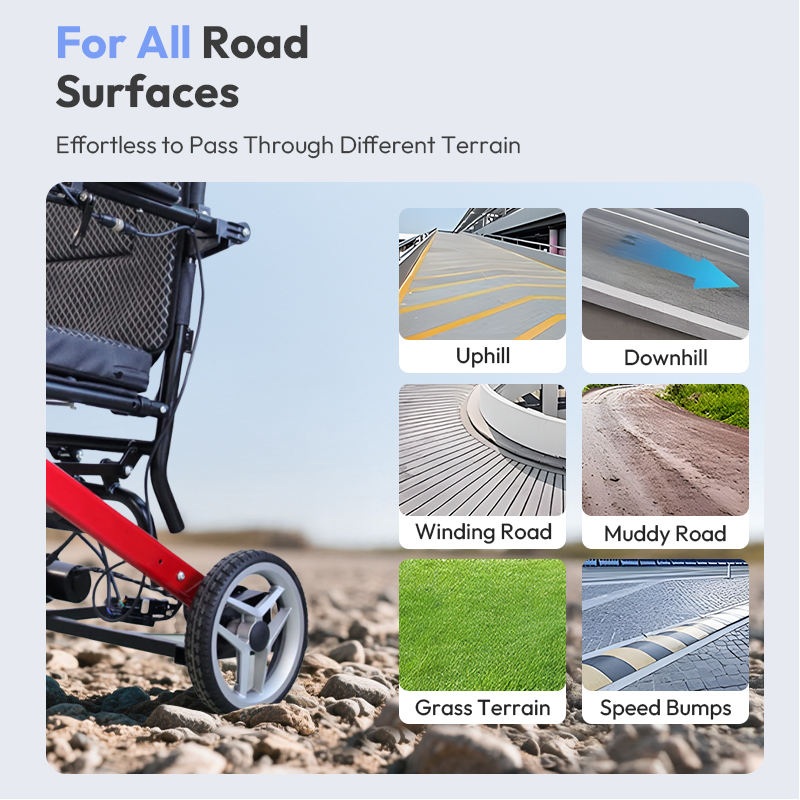

The 500-7 Electric Wheelchair represents a deliberate shift in this narrative. It isn’t merely a mobility aid; it is a masterclass in mechanical resilience, engineered for those who refuse to compromise on freedom. By achieving perfect kinematic synergy between dual 250W brushed motors and a high-density 6Ah lithium-ion architecture, this model delivers exceptional low-end torque without the bulk typical of heavy-duty units.

In this deep dive, we aren’t just listing specs. We are going to tear down the engineering nuances—from the molecular structure of the frame to the logic of the controller—that make this lightweight foldable power chair the smartest choice for the modern medical supply market. Whether you are a distributor looking for a reliable fleet addition or a user seeking independence, understanding the “why” behind the design is crucial.

The “Quick Specs” Snapshot

Before we dissect the mechanical intricacies, let’s establish the baseline engineering metrics. These aren’t just random numbers; they represent the specific intersection of portability, power, and structural durability that defines the 500-7.

| Specification | Engineering Value | User Benefit |

|---|---|---|

| Frame Material | Aerospace-Grade Aluminum Alloy (T6 Hardened) | High tensile strength, ultra-lightweight (approx. 23 kg). |

| Motor Configuration | Dual 250W Brushed Motors (500W Total) | High low-end torque for inclines; reliable serviceability. |

| Battery Tech | 6Ah Lithium-Ion (High Density) | Airline-approved mobility aid compliance; efficient range. |

| Braking | Intelligent Electromagnetic (EABS) | Passive safety; “Let go to stop” instant reaction. |

| Climbing Grade | 12-13 Degrees | Real-world capability for ramps and steep driveways. |

| Tires | Solid PU (Polyurethane) | Puncture-proof reliability with shock-absorbing density. |

| Turning Radius | 360-Degree Differential Steering | Spin-on-a-dime maneuverability for tight indoor spaces. |

1. The Aerospace-Grade Aluminum Alloy Frame

The chassis is the skeleton of any vehicle, and in the world of portable mobility, material choice is everything. The 500-7 utilizes an aerospace-grade aluminum alloy frame, specifically treated with a T6 hardening process.

Why T6 Hardening Matters

You might ask, “Why not just standard aluminum?” Standard aluminum is light, but it can be soft. T6 tempering involves a two-step thermal process: solution heat treatment followed by artificial aging. This realigns the crystal lattice structure of the metal, significantly increasing its yield strength. This allows the 500-7 to offer the tensile strength comparable to mild steel but at a fraction of the density.

Anodic Oxidation: More Than Skin Deep

Furthermore, the frame undergoes anodic oxidation. This isn’t just a paint job that chips off. Anodizing creates a passivated oxide layer integrated into the metal substrate itself. This renders the frame virtually impervious to corrosion from humidity, sweat, or environmental pollutants (like salt air near the coast). For users who live in humid climates or enjoy outdoor activities, this structural integrity ensures the chair remains safe and rigid for years, not just months.

If you are interested in seeing how this material standard applies across different form factors, take a look at our wider wheelchair series , where durability is a non-negotiable baseline.

2. Optimized Weight Distribution Geometry

Engineering a safe mobility device requires a deep understanding of physics, specifically the center of mass and vector forces. One common complaint with lightweight chairs is “tippiness” on inclines. The 500-7 addresses this through optimized weight distribution geometry.

By placing the heaviest components—the dual motors and the battery pack—low and central within the chassis, the engineers have lowered the center of gravity (COG) significantly. This geometric stability is crucial when you are navigating a 12-degree slope.

Kinematic Synergy

The design achieves a “kinematic synergy” where the frame geometry works with the propulsion system. When the motors engage high torque to climb, the low COG prevents the front casters from lifting, keeping you grounded. This is superior to rear-heavy designs that rely solely on anti-tip wheels to prevent flipping. Here, the frame geometry itself is the primary safety mechanism.

3. The 6Ah Lithium-Ion Power Cell

In the realm of compact travel wheelchairs, the battery is often the most misunderstood component. The 500-7 moves away from heavy, outdated lead-acid chemistry in favor of a 6Ah lithium-ion battery.

Why Lower Amp-Hours Don’t Mean Less Freedom

A common misconception is that you need massive 20Ah batteries for daily use. However, thanks to high-density energy storage, this 6Ah pack is deceptive. It provides a highly efficient range (up to 20km depending on terrain) without burdening the user with dead weight.

This specific capacity is strategically chosen for one major reason: Flight Compliance Engineering. According to IATA (International Air Transport Association) regulations, lithium batteries must typically be under 300Wh to be carried on passenger aircraft. A 24V 6Ah battery sits at roughly 144Wh, placing it safely within the “green zone” for air travel. This makes the 500-7 a truly global companion.

Battery Management System (BMS)

Longevity is ensured by a sophisticated BMS that balances the cells during charging and discharging. This prevents the “memory effect” and protects against over-voltage or deep discharge, ensuring that your battery survives hundreds of cycles while maintaining peak efficiency.

4. Dual 250W Brushed Motor Configuration

Propulsion in the 500-7 is handled by dual 250W brushed motors. In an era where brushless motors are buzzing in tech circles, the engineering choice to use brushed technology here is deliberate, pragmatic, and rooted in reliability.

The “Grunt” Factor: Low-End Torque

Brushed motors are renowned for their exceptional low-speed torque. When a user initiates a climb or navigates over a threshold (like a thick carpet edge or a door frame), they need immediate power now, without high RPMs. The dual 250W brushed motors deliver this “grunt” instantly. This high starting torque is essential for a high-torque climbing ability, ensuring you don’t get stuck on the transition from curb to road.

Thermal Dissipation Management

A critical aspect of these motors is thermal dissipation. The motor housings are designed with specific thermal pathways to shed heat generated during continuous operation. This prevents performance throttling during long operational periods or extended hill climbs, ensuring the load-bearing capacity remains consistent from the start of the ride to the finish.

Serviceability vs. Complexity

From a distributor and maintenance perspective, brushed motors lower the Total Cost of Ownership (TCO). They are robust, rugged, and if they ever do need service, the technology is understood by mechanics globally. There is no complex electronic speed controller (ESC) to fail catastrophically; it’s proven, durable physics.

5. Electromagnetic Braking System Integration

Safety in electric mobility is binary: the device must move when commanded and stop instantly when not. The 500-7 employs a sophisticated electromagnetic braking system (EABS).

The Science of “Let Go to Stop”

Unlike mechanical handbrakes that rely on friction pads and user grip strength, EABS is a “fail-safe” mechanism. The physics are straightforward yet brilliant:

- Default State (Locked): Strong springs mechanically clamp the brakes when no power is applied.

- Active State (Moving): When you push the joystick, current flows to a magnetic coil, creating a field that pulls the brake pads open, allowing movement.

- Stop State: The moment you release the joystick—or if the battery dies completely—the magnetic field collapses, and the springs instantly slam the brakes shut.

This means that even on a steep slope, gravity cannot overcome the brakes. You don’t need to react fast; you just need to let go. This passive safety mechanism is a requirement for any serious portable medical device.

6. One-Touch Folding Mechanism Mechanics

Portability is the defining feature of the lightweight electric wheelchair category. The 500-7 features a quick-fold mechanism engineered to withstand over 10,000 cycles of opening and closing.

This isn’t a simple hinge found on a lawn chair. It is a stress-tested articulation point designed to collapse the rigid frame into a compact footprint in seconds. The engineering challenge here is “torsional rigidity”—ensuring that when the chair is unfolded, it feels like a solid, single piece of metal with zero “wobble.” Through the use of locking pins and reinforced joints, the frame exhibits the stability of a rigid chair while offering the flexibility of a travel unit.

For those who prioritize this feature, the 500-7 sets a high bar for convenience in our lightweight electric wheelchair collection.

7. Precision Joystick Control Module

The interface between man and machine is the precision joystick control. This module uses sensitive potentiometers to translate subtle hand movements into digital signals for the motor controllers.

Differential Steering Logic

Because the 500-7 uses two independent motors, it doesn’t turn like a car. It uses differential steering logic. To turn right, the left motor speeds up while the right motor slows down or reverses.

- The Result: A 360-degree turning radius.

- The Benefit: You can spin within the chair’s own footprint. This is a game-changer for navigating tight medical offices, elevators, or narrow home hallways where a standard scooter would get stuck.

8. Solid PU Tire Compound Analysis

Flat tires are the nemesis of independence. The 500-7 eliminates this risk entirely through the use of puncture-proof solid PU tires. However, historically, solid tires meant a “bone-shaking” ride.

Molecular Density and Comfort

To combat the harshness usually associated with solid wheels, engineers utilize a specific Polyurethane (PU) compound with a varied molecular density. The outer layer is tough to resist abrasion, while the inner core is slightly softer to mimic the pneumatic cushioning of air.

Combined with an ergonomic seat dampening architecture—where the frame itself is designed to absorb micro-vibrations—this system significantly reduces spinal impact when rolling over cobblestones or uneven pavement.

9. Anti-Tip Wheel Vectoring

Safety isn’t just about stopping; it’s about stability. The anti-tip safety features on the 500-7 are not an afterthought. They are positioned based on calculated rear-extension angles.

When the wheelchair climbs a steep gradient (up to its 13-degree limit), the center of gravity shifts backward. The anti-tip wheels are positioned to catch the ground at the precise moment the front wheels would become light, “vectoring” the backward momentum into the ground and stabilizing the chassis. This allows users to tackle accessible ramps and driveways with total confidence.

10. Weather-Sealed Electronic Connections

Reliability means working when conditions aren’t perfect. The controller unit and battery connections in the 500-7 feature IP-rated weather sealing. This shields vital circuitry from high humidity and unexpected splashes.

While no electric wheelchair is a submarine, this maintenance-free motor configuration is designed to withstand the realities of daily life—whether that’s a sudden drizzle while waiting for a taxi or the humid environment of a seaside resort.

11. Maintenance-Friendly Modular Design

For distributors and rental fleets, the 500-7 is a dream. The engineering philosophy here is “Modular Replacement.”

- Motors: Can be unbolted and swapped in under 10 minutes.

- Controller: Plug-and-play connectors mean no soldering is required for repairs.

- Battery: Slotted rail design allows for instant swapping.

This reduces downtime significantly. Unlike complex integrated systems where a single failure bricks the whole unit, the 500-7 allows for targeted, rapid repairs, ensuring the user is back on the move quickly.

Conclusion: The Sum of Its Parts

The 500-7 Electric Wheelchair stands as a testament to balanced engineering. It doesn’t chase the highest speed or the largest battery at the expense of weight. Instead, it focuses on the metrics that matter to the actual user: reliability, portability, and torque.

From the T6-hardened structural durability of its frame to the kinematic synergy of its drive train, every component has been stress-tested to ensure it meets the demands of the real world. It offers the safety of an electromagnetic braking system, the convenience of being an airline-approved mobility aid, and the comfort of a suspension-tuned ride.

For those navigating the complex world of medical mobility, the 500-7 proves that you don’t need to choose between a portable chair and a powerful one. You just need the right engineering.

Ready to experience the difference? Explore how the 500-7 fits into our broader wheelchair series or dive deeper into our specialized lightweight electric wheelchair options today.