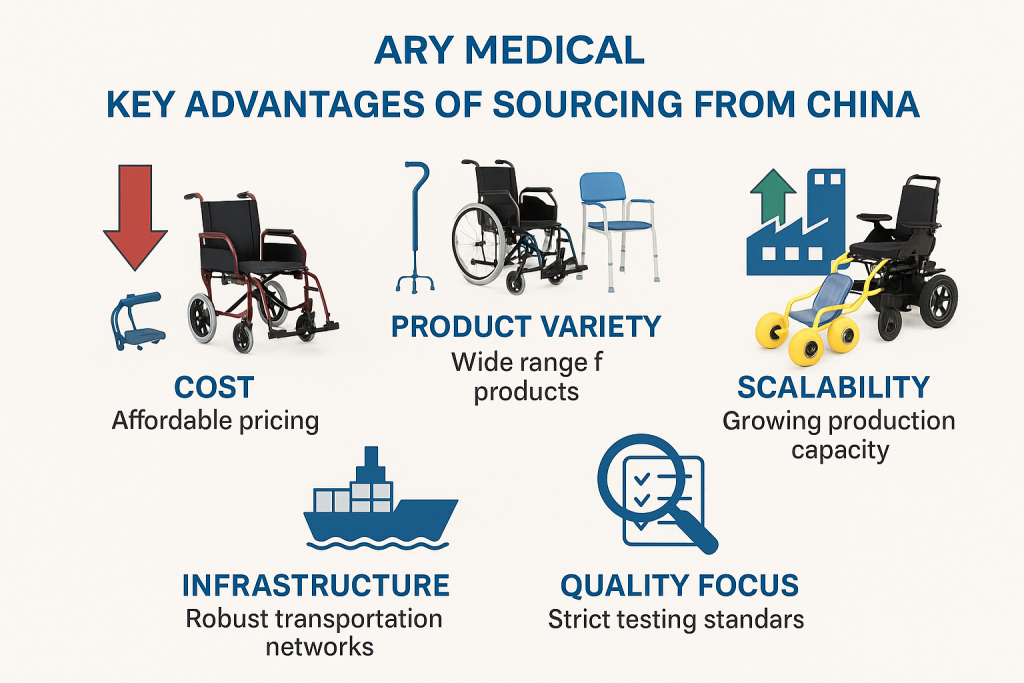

- Cost-Effectiveness: Generally, manufacturing costs in China can be lower due to economies of scale, established supply chains for raw materials, and efficient production processes. This often translates into more competitive pricing for distributors, allowing for better margins or more attractive retail prices for end-users. I’ve seen many businesses significantly improve their profitability by strategically sourcing from China.

- Vast Product Variety and Innovation: China’s manufacturing ecosystem is incredibly diverse. You can find suppliers for virtually any type of mobility aid, from standard walkers and manual wheelchairs to highly specialized equipment like all-terrain beach wheelchairs or advanced electric scooters. Furthermore, many Chinese manufacturers are increasingly investing in R&D, leading to innovative product designs and features. Ary Medical, for instance, prides itself on its range of specialized products, including unique items like floating wheelchairs.

- Scalability and Manufacturing Capacity: Chinese factories often have significant production capacities, making them well-suited to handle large-volume orders from international distributors. This scalability is crucial for businesses looking to grow and meet increasing market demand.

- Established Export Infrastructure: China has a well-developed export infrastructure, including logistics networks, ports, and customs processes, which facilitates international trade. Experienced suppliers are adept at navigating these systems.

- Growing Focus on Quality: While historical perceptions might vary, I’ve observed a significant shift towards higher quality standards among reputable Chinese manufacturers. Many, like Ary Medical, are obtaining international certifications (ISO, CE, FDA registration where applicable) and implementing robust quality management systems to meet the expectations of discerning global markets.

These advantages, when leveraged correctly, can provide a substantial competitive edge to distributors in the global medical mobility market.

Step 1: Identifying and Vetting Potential Suppliers in China – Your Due Diligence Checklist

The foundation of successful sourcing lies in finding the right supply partners. This requires a methodical approach to identification and vetting. Don’t just jump at the first supplier you find on a B2B platform. Here’s what I recommend:

Where to Find Potential Suppliers:

- Online B2B Marketplaces: Platforms like Alibaba, Made-in-China, and Global Sources are common starting points. They list numerous manufacturers and trading companies. Ary Medical, for example, utilizes Alibaba International Station.

- Industry Trade Shows and Exhibitions: Attending major medical device or healthcare trade shows (both in China and internationally) can provide direct interaction with potential suppliers. This was a key channel for our persona, David Thompson.

- Industry Associations and Directories: Relevant industry associations in China may have member directories.

- Referrals and Networking: Leverage your existing network. Sometimes the best suppliers are found through recommendations from trusted contacts.

- Direct Online Research: Use search engines with specific keywords (e.g., “beach wheelchair manufacturer China,” “rehabilitation supplies factory CE certified”).

Key Vetting Criteria – Digging Deeper:

Once you have a list of potential suppliers, the critical vetting process begins. This is where you separate the wheat from the chaff.

- Company Background and Legitimacy:

- Business License and Registration: Verify their official registration and business scope. This is a basic but crucial first step.

- Years in Business and Export Experience: How long have they been operating? More importantly, how long have they been exporting to your region or similar markets (e.g., Europe, North America)? Ary Medical’s experience exporting to South America, Europe, North America, and Asia is a positive indicator.

- Factory vs. Trading Company: Understand if they are a direct manufacturer or a trading company. Both have pros and cons. Manufacturers (like Ary Medical, which is an industry and trade integration) may offer better control over production and potentially lower prices, while trading companies might offer a wider product range from multiple factories and more experience in export processes. An integrated model like Ary Medical’s aims to combine the best of both.

- Company Size and Capacity: Assess if their production capacity (e.g., Ary Medical’s 50-person team) can meet your volume requirements and growth projections.

- Product Quality and Range:

- Product Specifications: Obtain detailed specification sheets for the products you’re interested in. Do they meet your technical requirements?

- Materials Used: Inquire about the materials and components. Are they durable and suitable for medical use?

- Sample Evaluation: This is non-negotiable. Always request samples to assess the build quality, functionality, and finish firsthand. This was a key step in David Thompson’s buying journey.

- Product Portfolio Breadth and Depth: Does their range align with your current and future needs? A supplier like Ary Medical, offering a one-stop service for various mobility aids, can simplify your sourcing significantly.

- Certifications and Compliance – The Deal Breakers:

- Quality Management System (QMS): Do they have ISO 13485 certification (specific to medical devices)? This is a strong indicator of a commitment to quality.

- Product-Specific Certifications: Depending on your target market, verify if their products have necessary certifications like CE marking for Europe or FDA registration/approval for the USA. This is a major pain point for buyers if overlooked.

- Test Reports: Request third-party test reports for critical safety and performance parameters.

- Communication and Support:

- Responsiveness and Language Proficiency: How quickly and clearly do they respond to your inquiries? Are their sales and support staff proficient in English (or your preferred language)? This addresses a common communication barrier.

- Technical Support: What level of technical support do they offer, both pre-sales and post-sales?

- Understanding of Your Market: Do they demonstrate an understanding of the specific needs and preferences of your target customers?

- Pricing, Payment Terms, and MOQs:

- Transparent Pricing: Obtain clear and detailed quotations, including Incoterms (e.g., FOB, CIF).

- Payment Terms: What are their standard payment terms? Are they negotiable?

- Minimum Order Quantities (MOQs): Ensure their MOQs are viable for your business model.

- Factory Audits (If Feasible):

- For significant partnerships, consider conducting an on-site factory audit or hiring a third-party inspection service. This provides invaluable insights into their production processes, quality control measures, and working conditions.

I always advise clients to create a supplier scorecard based on these criteria to objectively compare potential partners.

Step 2: Ensuring Quality and Compliance – Your Shield Against Problems

Sourcing medical devices means quality and compliance are not just desirable; they are absolutely critical. Failure here can lead to product recalls, legal liabilities, and severe damage to your brand reputation.

Establishing Clear Quality Standards from the Outset:

- Detailed Product Specifications: Provide your supplier with unambiguous specifications, including materials, dimensions, performance criteria, and any specific features required for your market. Don’t leave room for interpretation.

- Quality Agreements: For long-term partnerships, consider a formal Quality Agreement that outlines responsibilities for quality control, inspection procedures, and handling of non-conforming products.

- Golden Samples: Once you approve a pre-production sample, keep it as a “golden sample” – the benchmark against which all future production should be compared.

The Role of Inspections:

Inspections are your eyes on the ground. Don’t rely solely on the factory’s internal QC.

- Pre-Shipment Inspection (PSI): This is the most common and often most critical. A third-party inspector (or your own representative if feasible) checks a statistically significant sample of the finished goods before they are shipped. They verify quantity, specifications, workmanship, packaging, and labeling.

- During Production Inspection (DUPRO): Useful for large orders or when new suppliers are involved. It allows for early detection of issues, preventing larger problems down the line.

- Incoming Materials Inspection: While often done by the factory, understanding their process for inspecting raw materials and components is important.

📊 Comparison of Inspection Types

| Inspection Type | Description | Pros | Cons |

|---|---|---|---|

| PSI (Pre-Shipment Inspection) | Final inspection before shipment, usually when 80–100% of goods are packed | ✔️ Verifies product quality before delivery ✔️ Helps avoid defective shipments ✔️ Required by many buyers | ❌ Too late to fix issues at this stage ❌ Delays may affect shipping schedule |

| DUPRO (During Production Inspection) | Conducted when 20–80% of production is completed | ✔️ Detects defects early in the process ✔️ Allows correction before final packaging ✔️ Good for long production runs | ❌ May not reflect final product quality ❌ May require multiple visits |

| Incoming (Incoming Material Inspection) | Inspection of raw materials or components before production begins | ✔️ Prevents quality issues at the source ✔️ Ensures supplier reliability ✔️ Essential for high-precision products | ❌ Cannot detect process-related issues ❌ Slows down initial production if not well planned |

Navigating International Certifications (FDA, CE, etc.):

This is often a major hurdle for distributors. As David Thompson’s persona highlights, compliance issues are a significant pain point.

- Understand YOUR Market’s Requirements: The specific certifications needed depend on where you plan to sell the products. CE marking is mandatory for most medical devices sold in the European Economic Area. The FDA regulates medical devices in the United States, with varying requirements based on device classification.

- Verify Supplier Claims: Don’t just take a supplier’s word for it that they have “CE/FDA.” Request copies of certificates and verify their authenticity and applicability to the specific products you are sourcing. Check the issuing body’s database if possible.

- For CE Marking: Ensure the Declaration of Conformity is available, and if a Notified Body was involved, verify their details.

- For FDA: Check the FDA registration and listing database for the manufacturer and the specific device.

- Technical File/Design Dossier: Reputable manufacturers should have a technical file (for CE) or design history file (related to FDA requirements) for their products, demonstrating how they meet the essential requirements.

- Labeling and Instructions for Use (IFU): Ensure these comply with the regulatory requirements of your target market, including language, symbols, and necessary warnings.

I’ve seen many distributors stumble here. It’s an area where meticulous attention to detail is crucial. Partnering with a supplier like Ary Medical, who is experienced in exporting to compliant-heavy markets like Europe and North America, can alleviate some of this burden, but the ultimate responsibility for compliance in your market rests with you, the distributor.

Step 3: Logistics, Shipping, and Importation – Getting Your Products to Market

Once you have quality products ready, the next phase is getting them from the factory in China to your warehouse.

Understanding Incoterms:

Incoterms (International Commercial Terms) define the responsibilities of buyers and sellers in international shipping. Common terms include:

- EXW (Ex Works): You (the buyer) are responsible for all costs and risks from the factory door.

- FOB (Free On Board): The supplier is responsible for costs and risks until the goods are loaded onto the shipping vessel at the designated port in China. You take over from there.

- CIF (Cost, Insurance, and Freight): The supplier pays for the cost and freight to bring the goods to the port of destination. They also procure insurance. Risk transfers to you once the goods are on board the vessel.

Understanding these terms is vital for calculating your total landed cost. I generally find FOB to be a good balance for experienced importers as it gives them control over the main freight leg.

Choosing a Freight Forwarder:

A good freight forwarder is an invaluable partner. They can handle:

- Booking cargo space (sea or air freight).

- Inland transportation in China and your country.

- Customs clearance at both ends.

- Cargo insurance.

- Warehousing and distribution if needed.

Get quotes from multiple forwarders and choose one with experience in handling medical devices and shipping from China to your specific country.

Customs Clearance and Duties:

- HS Codes: Ensure the correct Harmonized System (HS) codes are used for your products. This determines the import duties and taxes applicable.

- Import Documentation: Prepare all necessary import documents, which typically include the commercial invoice, packing list, bill of lading (or air waybill), and any required certificates (e.g., Certificate of Origin, CE Declaration of Conformity).

- Duties and Taxes: Be aware of the import duties, VAT/GST, and any other taxes applicable in your country. Factor these into your landed cost calculations.

Managing Lead Times and Inventory:

- Production Lead Times: Get realistic production lead times from your supplier.

- Shipping Times: Sea freight from China to Europe or North America can take several weeks. Air freight is faster but significantly more expensive.

- Inventory Planning: Balance the need to have sufficient stock with the costs of holding inventory. This is a key pain point for David Thompson. Consider factors like seasonal demand (e.g., for beach wheelchairs in summer).

Step 4: Building Strong, Long-Term Supplier Relationships – The Key to Sustained Success

Sourcing from China shouldn’t be about one-off transactions. Building strong, long-term relationships with reliable suppliers like Ary Medical is crucial for sustained success. This aligns with David Thompson’s preference for relationship-oriented partnerships.

Effective Communication:

- Clarity and Precision: Be clear, concise, and precise in all your communications. Avoid ambiguity, especially when discussing technical specifications or quality requirements.

- Utilize Multiple Channels: While email is good for formal documentation, tools like WhatsApp or WeChat (as mentioned by David) can be useful for quick updates, but always confirm important agreements in writing.

- Bridge Cultural Gaps: Be mindful of potential cultural differences in communication styles and business etiquette. Patience and a willingness to understand are key.

- Regular Contact: Maintain regular contact, not just when placing orders or facing problems. Share market feedback and discuss future plans.

Trust and Transparency:

- Be a Good Partner: Pay on time, provide clear forecasts where possible, and be transparent about your market and expectations.

- Mutual Respect: Treat your suppliers as partners, not just vendors. A respectful relationship fosters better cooperation.

- Address Issues Constructively: When problems arise (and they sometimes do), address them professionally and focus on solutions rather than blame.

Visiting Your Suppliers:

If possible, visit your key suppliers in China periodically. Face-to-face meetings can significantly strengthen relationships and provide deeper insights into their operations.

Continuous Improvement:

- Performance Reviews: Regularly review your supplier’s performance against agreed KPIs (e.g., on-time delivery, quality acceptance rates).

- Collaborate on Improvements: Work with your supplier to identify areas for improvement in products, processes, or communication.

I have found that investing in these relationships pays dividends in terms of reliability, preferential treatment, and a willingness from the supplier to go the extra mile when needed.

Ary Medical: Your Experienced Partner in Sourcing from China

At Ary Medical, we understand the challenges and opportunities that international distributors face when sourcing medical mobility aids from China. As an industry and trade integrated company with a 50-strong team, we are committed to providing:

- A Diverse Range of Quality Products: From beach wheelchairs and floating wheelchairs to electric scooters and walkers, all manufactured with attention to quality and compliance.

- Export Expertise: We have a proven track record of exporting to demanding markets in South America, Europe, North America, and Asia.

- Focus on Compliance: We understand the importance of certifications like CE and work to meet international standards.

- Collaborative Partnerships: We aim to build long-term, mutually beneficial relationships with our distributors.

[ Explore Ary Medical’s full product catalog here.]

Conclusion: Your Gateway to Quality and Growth

Sourcing high-quality mobility aids from China can be a highly rewarding venture for international distributors, offering access to innovation, variety, and cost-effective solutions. By implementing a strategic approach to supplier identification and vetting, prioritizing quality and compliance, managing logistics effectively, and fostering strong supplier relationships, you can navigate the complexities and unlock significant growth opportunities. The journey requires diligence and commitment, but with the right knowledge and reliable partners like Ary Medical, you can build a resilient and profitable supply chain that meets the evolving needs of your customers worldwide.

Thank you for taking the time to read this guide. I trust it will serve you well in your sourcing endeavors.

[Editor Note: This post aims to be a definitive guide for distributors. Key ranking factors will include comprehensiveness, actionable advice, and addressing specific pain points of international distributors sourcing from China (quality, compliance, logistics). Highlighting Ary Medical’s experience and capabilities as a reliable Chinese supplier within this context is crucial. Competitors might offer generic advice; this should be practical and directly relevant to a distributor’s operational needs. Ensure to include keywords related to importing from China, medical device distribution, quality control, and international certifications.]

Recommended Reading:

- [ Ary Medical case study of a successful distributor partnership]

- [ external resource on navigating Chinese business culture for importers]