In a nutshell: For B2B purchasers of medical equipment, the efficiency and reliability of the supply chain are paramount. Ary Medical’s integrated industry-trade model offers a distinct “factory-to-facility” advantage, streamlining processes from manufacturing to delivery. This article explores how this integration translates into enhanced quality control, stable supply, cost efficiencies, and greater responsiveness, providing a superior procurement experience for hospitals, distributors, and retailers.

The Quest for Seamless Procurement: Why an Integrated Supply Model Matters

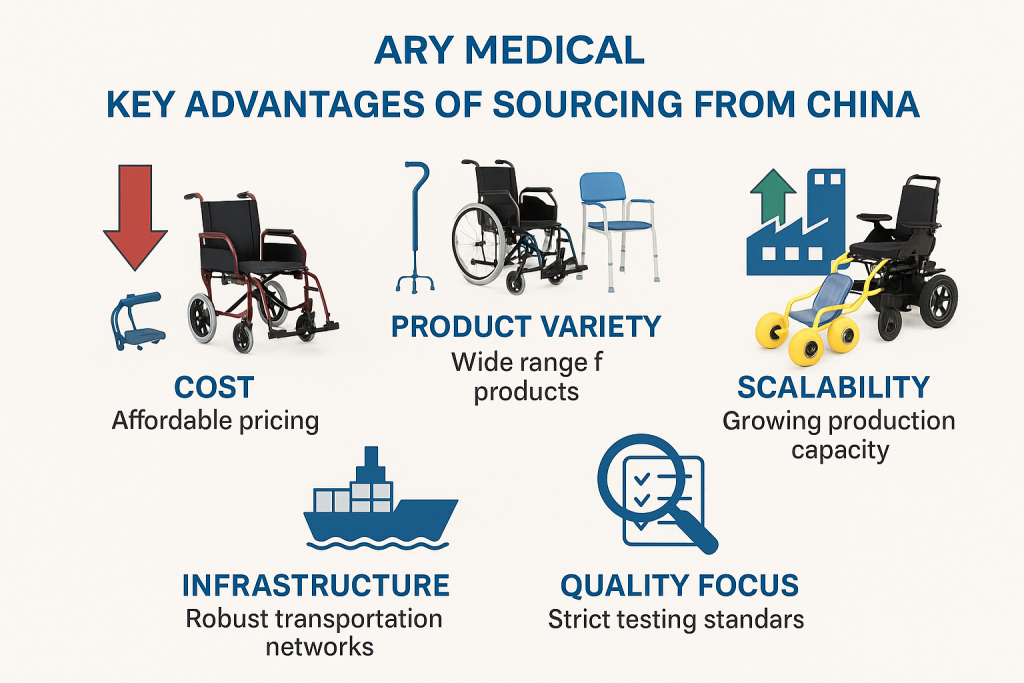

In the complex ecosystem of medical device procurement, B2B buyers like yourself are constantly seeking ways to optimize efficiency, ensure quality, and maintain a reliable flow of essential supplies. Whether you are outfitting a hospital, stocking a distribution warehouse, or curating products for a retail chain, the journey from the factory floor to your facility can be fraught with potential bottlenecks, communication gaps, and quality control challenges. Traditional, fragmented supply chains, often involving multiple intermediaries, can obscure visibility and dilute accountability. Our persona, David Thompson, a Senior Procurement Manager, highly values streamlined operations and a reliable supply chain – goals that are often compromised in disjointed systems. This is where an integrated supply model, particularly one that combines manufacturing insight with trading expertise, offers a compelling alternative. Ary Medical’s approach as an industry and trade integrated company provides a more direct, controlled, and efficient pathway for products like electric wheelchairs, all-terrain walkers, beach wheelchairs, and crutches to move from their point of origin to your point of need. This article will delve into the specific advantages of this “factory-to-facility” edge and how it benefits your organization.

Understanding the Integrated Industry-Trade Model: Ary Medical’s Foundation

Before we explore the benefits, let’s clarify what we mean by an “integrated industry-trade model.” Unlike a pure manufacturer that might lack sophisticated export capabilities, or a pure trading company that has no direct control over production, Ary Medical combines key aspects of both. This means we have:

- Direct Involvement or Close Partnership with Manufacturing: This gives us significant insight into and influence over the production processes, quality control systems, material sourcing, and capacity planning. It’s not just an outsourced relationship; it’s a deeply intertwined one.

- In-House Trading and Export Expertise: Our team possesses the commercial acumen, logistical knowledge, and market understanding required to manage international sales, export documentation, shipping, and customer relations effectively. Our experience exporting to South America, Europe, North America, and Asia is a testament to this.

This dual capability forms the bedrock of our factory-to-facility advantage. It allows us to offer a more holistic and controlled service than many traditional suppliers.

[Image: A diagram illustrating Ary Medical’s integrated model, showing a seamless flow from raw materials/factory through quality control, logistics, and finally to the B2B client’s facility.]

The Factory-to-Facility Edge: Tangible Benefits for B2B Buyers

This integrated structure translates into several critical advantages for our B2B partners:

1. Enhanced Quality Control and Consistency: From Production Line to Your Doorstep

When a supplier has direct oversight of manufacturing, the ability to implement and monitor quality control is significantly enhanced.

- End-to-End Quality Management: We can ensure that quality standards are not just checked at the final stage but are embedded throughout the manufacturing process – from the inspection of incoming raw materials for our walkers and electric scooters to in-process checks and rigorous final product testing.

- Direct Feedback Loop: Any quality concerns or requirements for modification can be communicated more directly and efficiently to the production floor, leading to faster resolutions and continuous improvement.

- Reduced Risk of Substandard Products: This hands-on approach minimizes the chances of defects or non-conformities, ensuring that the products arriving at your facility meet your specifications and the expectations of your end-users. This directly addresses David Thompson’s pain point regarding inconsistent quality.

I’ve seen many instances where a lack of direct manufacturing linkage leads to quality drift or difficulties in implementing specific quality requirements. Our model is designed to prevent this.

2. Greater Supply Chain Stability and Reliability: Dependable Delivery

Ary Medical’s competitive advantage explicitly mentions “stable supply and production” due to our integrated model. This is a crucial benefit for B2B buyers who need predictability.

- Improved Production Planning: Direct insight into manufacturing capacity and schedules allows for more accurate lead time estimations and better coordination of production with demand forecasts.

- Proactive Issue Resolution: If production challenges arise (e.g., material shortages in the broader market), our closer connection to the factory floor allows for earlier detection and more agile problem-solving to minimize impact on delivery schedules.

- Reduced Reliance on External Variables: While no supply chain is immune to all disruptions, our model reduces the number of external parties and hand-offs involved, thereby minimizing potential points of failure.

For a procurement manager like David Thompson, whose primary goal is a reliable supply chain, this stability is invaluable.

3. Increased Cost-Effectiveness and Value: Optimizing the Supply Chain

Streamlining the supply chain by reducing intermediaries and improving efficiency can lead to better overall value.

- Reduced Markups: Fewer layers in the supply chain can mean fewer markups, potentially leading to more competitive pricing for high-quality medical devices.

- Optimized Logistics: Consolidating operations and having in-house export expertise can lead to more efficient shipping and logistics arrangements, reducing transportation costs.

- Lower Costs Associated with Poor Quality: Consistent quality means fewer returns, less rework, and lower warranty-related expenses, contributing to a lower total cost of ownership.

While price is always a factor, our integrated model focuses on delivering superior value through a combination of quality, reliability, and efficiency.

4. Enhanced Responsiveness and Flexibility: Adapting to Your Needs

A more direct line from the customer to the factory floor facilitates greater responsiveness.

- Quicker Turnaround for Inquiries and Orders: Communication flows more smoothly, leading to faster responses to product inquiries, quotation requests, and order processing.

- Greater Agility for Customization: As discussed in a previous article, our integrated model is a key enabler for handling requests for customization of products like our all-terrain wheelchairs or beach wheelchairs. Design modifications or specific branding requirements can be discussed and implemented more efficiently.

- Adaptability to Market Changes: If market demands shift or new product requirements emerge, our closer connection to production allows for a more agile response in adapting our offerings.

This responsiveness is crucial in the dynamic medical device market, where needs can evolve rapidly.

5. Improved Transparency and Communication: A Clearer View

Dealing with an integrated supplier often means greater transparency into the processes that affect your order.

- Clearer Production Updates: We can often provide more accurate and timely updates on the status of your orders as they move through the production cycle.

- Direct Access to Expertise: Our 50-person team includes individuals with both manufacturing and commercial expertise, providing you with knowledgeable contacts who can address a wider range of queries.

- Simplified Problem Resolution: If issues do arise, having a single, accountable partner with oversight of both production and trade aspects can simplify and expedite resolution.

[Link: If Ary Medical has a virtual factory tour or a page explaining its manufacturing partnerships, link it here.]

How Ary Medical’s Integrated Model Serves Diverse B2B Needs

Our factory-to-facility edge benefits various types of B2B clients:

- Hospitals and Large Healthcare Providers: Require consistent quality, reliable bulk supply, and often specific compliance documentation, all of which are better managed through an integrated system.

- International Distributors: Benefit from our export expertise, stable supply for their inventory planning, and the ability to offer a diverse range of products (like floating wheelchairs or electric mobility aids) sourced reliably from a single key partner.

- Retailers: Can confidently stock products knowing they come from a source with strong quality control and a stable supply chain, ensuring they can meet customer demand.

Regardless of the scale or nature of your B2B operation, the efficiencies and reliability offered by our integrated model provide a solid foundation for your procurement strategy.

The Journey: From Ary Medical’s Factory Floor to Your Facility

Let’s visualize the streamlined journey:

- Order Placement & Confirmation: Your requirements are clearly defined and confirmed with our expert team.

- Production Scheduling & Material Sourcing: The order is integrated into the production plan, with materials sourced through established quality channels.

- Manufacturing & In-Process QC: The products (e.g., walkers, crutches, specialized wheelchairs) are manufactured under strict quality controls.

- Final Quality Assurance & Testing: Finished goods undergo rigorous final inspection and testing to ensure they meet all specifications and compliance standards (e.g., CE marking requirements).

- Expert Packing & Export Preparation: Products are professionally packed for international transit, with all necessary export documentation prepared by our experienced trade team.

- Logistics & Shipping: We coordinate with reliable freight forwarders to ensure efficient and timely shipping to your designated port or facility.

- Post-Delivery Support: Our relationship continues with after-sales support and assistance as needed.

This managed, end-to-end process is designed to minimize hassle and maximize reliability for you.

Conclusion: Experience the Ary Medical Advantage in Integrated Supply

In the competitive landscape of medical device procurement, the efficiency, reliability, and quality assurance offered by an integrated industry-trade supplier provide a significant strategic advantage. Ary Medical’s factory-to-facility model is designed to streamline your supply chain, offering enhanced control over quality, greater stability in supply, improved cost-effectiveness, and superior responsiveness. By partnering with us, you are choosing a supplier that manages the critical path from manufacturing to your doorstep with expertise and a commitment to excellence. This allows you to focus on what you do best: serving your patients and customers with confidence.

We invite you to experience the benefits of a truly integrated supply partner. Thank you for reading.

[Editor Note: This article should clearly explain the benefits of Ary Medical’s specific business model (industry and trade integration) for B2B buyers. Focus on how this integration solves common supply chain problems like quality inconsistency, delays, and lack of transparency. Use strong, benefit-driven language. Competitors might be just factories or just traders; this article needs to show why Ary Medical’s combined approach is superior for the buyer. Keywords should include “integrated medical supply chain,” “factory direct medical equipment,” “China medical device manufacturer exporter,” “reliable B2B medical supplier,” and specific product names.